-

0086-15068518279 (Chinese)/001-5416026691 (English)

0086-15068518279 (Chinese)/001-5416026691 (English) -

[email protected]

[email protected]

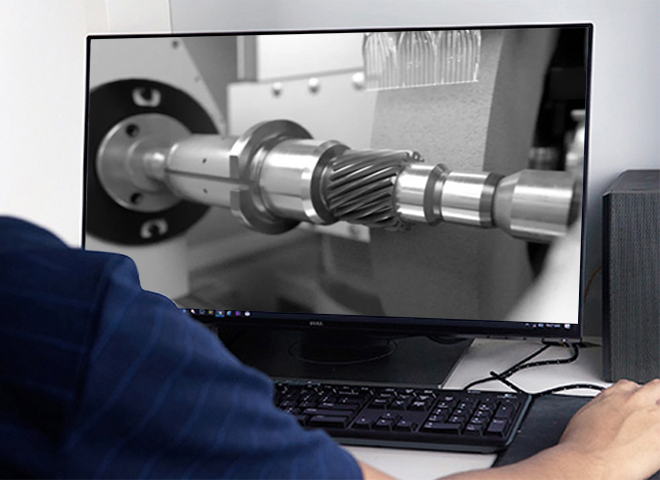

The performance of a machine is the result of the combined effect of all its components.

Our technical team consists of experienced engineers and technicians who are not only proficient in the operation and maintenance of grinders, but also have a deep understanding of material properties and processing technology. This enables us to provide customers with customized solutions to meet their specific processing needs.

By deeply studying the design and manufacturing process of precision grinding machines and paying great attention to configuration and construction from the beginning, our R&D team is able to provide high-performance equipment.

We understand the challenges faced by every industry and offer a wide range of grinding machine application production solutions to meet your specific production needs.

Materials and components are the most critical elements to affect the performance of the equipment.

We use high-quality raw materials and branded components to ensure that our high-performance machines have a long service life and short downtime.

In the field of precision machining, the pursuit of product precision is endless. Our grinder manufacturer is well aware of this, so we not only continue to make progress in production technology, but also invest a lot of resources in quality control and establish a professional laboratory that meets industry standards.

Our laboratory is equipped with a series of advanced measuring and testing equipment, including but not limited to Tokyo Precision's cylindricity meter, 3D coordinate measuring machine, profiler and laser interferometer, which can accurately measure and analyze the parts processed by the grinder. With these equipments, we can ensure that the processed parts meet customer requirements in terms of size and surface finish.